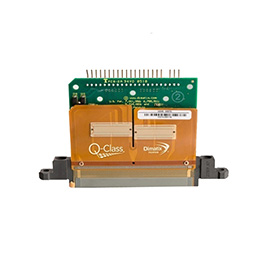

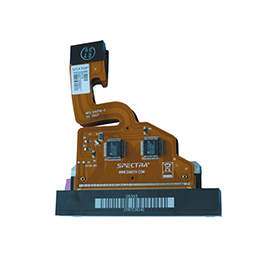

FUJI

FUJIFILM Dimatix/Fujifilm, formerly known as Spectra, an American industrial inkjet printhead manufacturer, was founded in 1984 and headquartered in Santa Clara, California, USA. Its research and manufacturing are concentrated in Santa Clara, California and New Hampshire, New Hampshire. Spectra initially produced office printed thermal foam printheads, but eventually abandoned the development of industrial piezoelectric printheads due to the emergence of HP. A stainless steel packaged lightweight containerized printhead with all components that can move quickly is characterized by small ink droplets (corresponding to high accuracy) and a very high spraying frequency (fast speed). For ink, the characteristics of the printhead are: Not very picky, suitable for high-performance printers. After being acquired by Fuji Film Company in July 2006, it was renamed Dimatix Inc. Fuji Film Dimatix mainly produces high-performance piezoelectric inkjet print heads. Its characteristic is comprehensive technology, and it is currently the only supplier that can meet various inkjet printing requirements. However, due to the high price of the product, its application is limited. Fujifilm company Dimatix's products use a technology called Share Roof, where all nozzles can be sprayed simultaneously, resulting in faster printing speed.

STARFIRE

StarFire? SG1024/MC is a compact independent device that can withstand harsh environments in industrial ceramic production. It uses materials that have been verified on-site, and through continuous ink recycling and monochrome operation, it continuously outputs at a speed of 400 points per inch through 1024 independent channels arranged in eight rows on a replaceable metal nozzle plate, providing consistent output over a longer lifespan. Wear resistance.

characteristic

Durable and repairable structural design

1024 independent control spray channels

Integrating Versadrop multi pulse and grayscale spray painting technology

An uninterrupted ink circulation system based on Redijetf technology

Detachable base design, specially coated metal nozzle panel

SAMBA

The Samba G3L print head technology has the breakthrough quality, speed, and scalability required for single pass inkjet printing and material deposition applications with variable width. The Samba G3L printhead is based on the most advanced silicon microelectromechanical system manufacturing (Si MEMS), which is the most advanced technology today.

characteristic

The only piezoelectric nozzle without glue in the Samba nozzle

Samba G3LSpec life: Trillion actions>1 trillion pulse life 4000 days of operation*/

Up to 10 years of design lifespan

SAPPHIRE

Combining top-notch grayscale operations to provide top-notch spraying accuracy. Its lightweight, slim design and configurability, as well as support for multiple ink formulations, make this print head size particularly suitable for scanning printer architecture and applications. 30 pL native droplet size.

characteristic

The print head has 256 independent channels

Arrange in a single row of nozzles with a spacing of 100 points per inch

Inject adjustable droplets of 30 to 80 liters in binary injection mode

Spray 30 liters of basic liquid droplets in grayscale mode

Resolution up to 900 dpi

POLARIS

Using VersaDrop jetting technology, the print head can perform binary adjustable operations with a maximum ink droplet size of 80 picliters and a resolution of 800 dpi.

characteristic

Featuring 512 independent channels arranged in multiple rowsPerform monochrome operations at intervals of 200 dots per inch

Or perform two color operations at intervals of 100 points per inch per inch

EMERALD

Unparalleled flexible operation modes include adjustable binary ink droplet size and grayscale functionality. The reliable on-site validated metal nozzle plate technology can provide precise droplet placement accuracy for various types of inks, including UV curing, solvents, and water-based.

characteristic

With 256 independent channels

Arrange in a single row of nozzles with a spacing of 100 points per inch

Spray adjustable droplets ranging from 30 to 80 liters

Spray 30 liters of basic liquid droplets in grayscale mode

NOVA

characteristic

S-Class

High performance, 128 channel inkjet components suitable for a wide range of printing applications. After calibration, it can provide a droplet size of 30 liters, suitable for resolutions up to 900 dpi.

characteristic

Two electrically independent piezoelectric slices, each with 64 addressable channels, providing a total of 128 jets. The nozzles are arranged in a straight line, with a distance of 0.020 inches between them. The resolution can reach up to 900 dpi.SKYWALKER

characteristic

50 μ L nominal droplet size

High frequency continuous operation

Specially designed to extend service life

Support solvent based ink formulation

Allow the use of high viscosity sprays

Stainless steel nozzle plate

GALAXY

A high-performance, sturdy and reliable nozzle designed for a wide range of industrial and commercial printing applications, such as wide graphics, addresses, and packaging, hot melt printing applications, with a resolution of up to 900 dpi.