KM

KMIJ Inkjet Technology Co., Ltd. is a subsidiary of Konica Minolta in Japan, established in 2005. After purchasing the patent usage rights of Sail Company, the company developed piezoelectric printing heads based on Sail technology. Its products are mainly in the middle and low end, and are mainly used in industries such as circuit printing, advertising printing, and textiles in the domestic market.

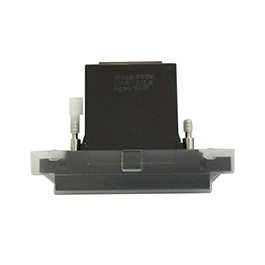

KM512

The high resolution of 360dpi allows for the arrangement of 512 nozzles on a compact print head. The KM512 series includes types L, M, and S, with corresponding unit ink droplets of 42pl, 14pl, and 4pl, respectively. Types M and S can be driven by 4-level grayscale modes, used to reproduce high-quality images with smooth tones

characteristic

Industrial inkjet printheads suitable for various applications

Shear mode, piezoelectric inkjet printhead

360dpi high resolution and 512 nozzles

Compatible with solvents, UV, oil and water

Compact design of print head installation system

KM512i

characteristic

KM1024

Compared to the KM512 nozzle, the number of nozzles has doubled to achieve higher density, thereby expanding the printing width to 72 millimeters. This wider printing width further enhances the applicability of the print head to printing systems that require high productivity (high-speed printing), such as one-way commercial printers.

characteristic

Up to eight different ink droplet sizes can be printed. This enables its use in new applications that require richer levels and higher definition image quality.KM1024i

The independent driving system makes the driving frequency (45 kHz) about three times higher than the current KM1024 series. This inkjet print head is an ideal choice for developing one-way inkjet printers that can print at high speeds.

characteristic

Like the existing KM1024 series, it is equipped with a high-performance IC. Can print up to 8 grayscale patterns.

This enables its use in new applications that require richer levels and higher image quality.

KM1800i

Designed for high-quality one-way printing systems. Mainly designed for UV ink, it can also be used for water-based inks or hot melt adhesive inks with high viscosity. Using validated batch piezoelectric technology, a 3.5pl ink droplet volume was provided with a resolution of 600dpi in a narrow space of 19.8mm.

characteristic

This nozzle is suitable for use with a circulating ink system, such as for white or metallic ink. The nozzle can be used in binary or grayscale (3 bit) mode.

KM1024a

Simulated waveforms are used to achieve high productivity and printing performance in multi drop continuous droplet injection. Furthermore, based on the characteristics of the ink, the degree of freedom in waveform design is greatly enhanced; It can be printed at 6pl/40kHz and 20pl/22kHz.

characteristic

The compact and lightweight 17.6mm/150g casing greatly reduces the load required for printer design. In addition, if the 1024i series is already in use, there is no need to change the mechanical design.New chemical resistance has been achieved for various inks of 1024aSAE-Q. The high reliability of the machine head, which has been proven in the past, has also been provided to water-based inks.