XAAR

Established in 1990, XAAR/Sail is a leading global independent supplier of industrial inkjet printheads, headquartered in Cambridge, UK. It was listed on the London Stock Exchange in 1997. Sail Company mainly designs, develops, and produces piezoelectric inkjet printheads. Its early main business was to transfer patent rights, and multiple Japanese companies have purchased its patent usage rights. After merging with MIT in Sweden in 1999, it established its own production base and currently has two production bases in Stockholm, Sweden and the United Kingdom. The early products of Sail Company were mainly aimed at the advertising and printing industry, with a high market share. Later, they were impacted by low-priced products, and their product focus gradually shifted to the ceramic printing and home decoration industries.

Nitrox

XaarNitrox is supported by ImagineX, providing unparalleled productivity and performance, so you can handle the most demanding applications.

characteristic

High speed printingPerfect printing

Print almost anything

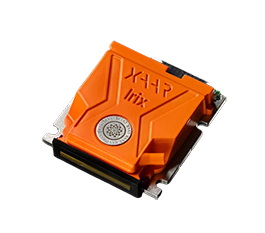

Irix

XaarIrix adopts ImagineX technology, providing excellent print quality and ease of use. It is a powerful and highly reliable print head, meaning you can print with confidence. Thanks to XaarIrix's highly accurate ink droplet position and uniformity, it can produce excellent printing quality even during long-distance printing. Reliable printing of every drop of each image for the first and every time, even in harsh environments, can prolong normal production operation time. Providing a fast and economical market path for anyone who wishes to enter the field of inkjet technology.

characteristic

Accurate printingReliable printing

Easy printing

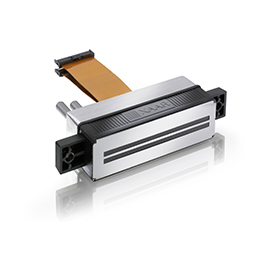

2002

The new Xaar2002 aims to provide excellent 720dpi printing resolution quality and performance for various applications, while also providing significantly improved color uniformity within the width range of the print head. Xaar's unique multiple technologies ensure continuous and reliable printing in one-way operations, maximizing output, minimizing production interruptions, and reducing the need for operator intervention. By using the descent in the alignment of the print head, mechanical tolerance improvements allow the print head to descend more easily into the printing rod. Therefore, setting the time faster, replacing the print head faster, and maximizing the normal running time of the printer.

characteristic

Excellent print quality for out of the box useContinuous and reliable printing keeps you worry free

Plug and play, accelerate setup and installation

1003

Compared to other nozzles suitable for one-way printing on the market, the Xaar1003 nozzle is a quality benchmark. This nozzle with comprehensive and high-performance features is developed based on the market leading Xaar1002 and its predecessor, the unique and pioneering Xaar1001. The new Xaar1003 print head series has launched an important new feature - XaarGuard ™– It can provide ultimate protection for the nozzle plate, combined with other design innovations, to achieve the longest maintenance free production period in the industry. In addition, due to Xaar's new X-ACT ™ The manufacturing process of microelectromechanical systems (MEMS) and the new Xaar1003 further improve the consistent printing quality across the entire width of wide printing for various one-way applications.

characteristic

Excellent printing quality

The highest productivity

Ultimate versatility

Patented technology for Sail nozzle protective plate

Driver calibration manufacturing process

TFTechnology ® technology

HybridSide Shooter ® architecture

2001+

Choosing to use Xaar2001+UV printhead optimized digital inkjet printing machine high deposition technology is of great commercial significance. Combining high-resolution and mature TF technology, Xaar2001+U ink recycling has set a new standard for the printing quality and reliability of digital printing, making it the most valuable printing head in the market today, suitable for various industrial applications.

characteristic

Excellent printing quality at high line speedsThe effect of varnish using high sedimentation rate (HL) technology

Continuous and reliable printing allows you to sleep without any worries

5601

The Xaar 5601 has excellent performance and is an ideal choice for printing textiles, fiber laminates, packaging, labels, commercial printing, and many other applications. The silicon MEMS manufacturing process used in the design and production of this nozzle has reduced the total cost of current digital inkjet machines, enabling equipment manufacturers to respond to new markets and seize new opportunities, thereby accelerating digitalization in major commercial and industrial printing applications.

characteristic

Xaar 5601 can generate high-quality digital printing at high speed.1200 nozzles per inch, 8 grayscale levels, and 3pL drop rate.

The Z-offset proofreading configuration can achieve a compact printing area, with a maximum

Maximize the positioning of ink droplets while minimizing the time for media expansion between printing rods.

1201

Xaar1201 is a printing head using thin film piezoelectric silicon micro electromechanical system (MEMS) technology, used for printing wide format graphics (WFG) and textiles using thermal transfer, weak solvent or water-based ink. It has 1280 spray holes, arranged in 4 rows, and can print 2 colors (600dpi) or 4 colors (300dpi original resolution). We provide OEM with excellent and guaranteed high-quality printing heads for the wide format graphics and textile printing market. The high printing speed, accuracy, and reliability achieved through MEMS technology make the Xaar1201 print head extremely suitable for both electrostatic and multiple printing applications.

characteristic

First class printing quality

Widely used

Easy to integrate

502

Whether it's printing large external banners or indoor sales point materials, this high-quality print head can provide excellent printing quality, excellent reliability, and longer production run times. The unique PrecisionPlus architecture of the Xaar502 print head series is built on the incredible success of Xaar's hybrid side projection architecture, and has been proven to be market leading by the Sail 1003 print head. This new architecture optimizes the performance of the actuator, making ink droplets more uniform and stable throughout the entire printing range, providing excellent printing quality for stunning graphics.

characteristic

Excellent printing quality

Industrial reliability

High production running time

501

Whether it's printing large external banners or indoor sales point materials, this high-quality print head can provide excellent printing quality, excellent reliability, and longer production run times. Xaar501GS8 can easily achieve value-added effects, such as printing or adding varnish on transparent or colored substrates. The ability to print high viscosity or heavily colored inks (such as white) using pulse mode TF technology has become a reality. The unique PrecisionPlus architecture is built on the incredible success of Xaar's hybrid side projection architecture, proving its market leading position with the Sail 1003 printhead. This new architecture optimizes the performance of the actuator, making ink droplets more uniform and stable throughout the entire printing range, providing excellent printing quality for stunning graphics.

characteristic

Excellent printing qualityIndustrial reliability

High production running time

128

Whether it's outdoor or indoor graphics, barcodes, outer box encoders, or poster printing, Xaar128 is compatible with many ink types. Xaar128 has a compact structure and diverse functions, and is widely used in various fields due to its high printing quality, high resolution, and multiple models, mainly for encoding and labeling as well as the WFG market. Recent manufacturing optimizations have enabled Xaar to provide programmable circuits for Xaar128, which offer advanced control and tuning of print heads, as well as better control over ink characteristics and print quality.

characteristic

Lightweight and powerfulEasy to integrate

318

The Xaar 318 series nozzle can provide extremely small ink droplets and Accurate placement in place, can be achieved through inkjet printers for photo matching Comparable image quality, while also meeting the needs of various professions Strict requirements in the field of printing.

characteristic

Xaar 318/CA4 can be used with various UV curable and oil-based inks

Water is widely used in the spray painting market and can produce

Maximize performance.

Sail's 318 series' grayscale 'nozzles can spray variable amounts

The amount of ink droplets allows the ink to be fully utilized.