Our process and engineering team, with decades of professional knowledge, has expanded the inkjet process of functional materials to industrial production levels. In all aspects of the printing process development, we are able to support the maximum needs of end-users and partners: inkjet print heads, fluid materials, substrates, drive devices, circulating ink supply, motion control, and integrated development of all related collaborations。

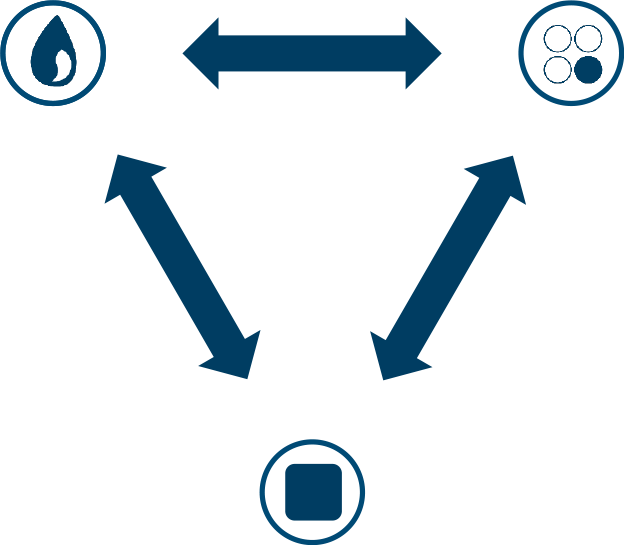

| Process development service process for new applications: | |||

|---|---|---|---|

|

We support optimizing your process and fine-tuning various coordination relationships between substrates, ink, print heads, and applications。 |

|

Digital manufacturing

Inkjet printing

The USP of the research institute is a unique combination of rich knowledge, unparalleled experience, state-of-the-art infrastructure, and extensive network required for efficient inkjet digital production. We have found innovative solutions at every step of the digital production process, from materials to the final product.

Digital production can be used to replace various fields of analog printing. Its successful implementation mainly depends on the appropriate formulation of functional inks and the availability of compatible printing and pre-processing or post-processing technologies. These are exactly our areas of expertise. When these technologies are not yet available, we are fully capable of developing them. Different process steps include ink formulation, its rheological properties, substrate pretreatment, printing, post-processing of printing layers, and development of prototype printers to ultimately demonstrate the feasibility of the process for the digital manufacturing of a given product. We can not only support our partners through these different steps, but also develop new technologies to expand the potential of digital production。

material

We use a variety of different materials to develop digital printing processes: pigments, silver, copper, gold or ceramic nanoparticles, graphene sheets, carbon nanotubes, cells, proteins, and photon balls, to name just a few examples. Daily use of UV, solvents, water, oil, and even electron beam ink. According to the customer's application requirements, existing ink can be used directly or new ink can be prepared. We can rely on strong partnerships with global ink manufacturers to obtain the most suitable materials and develop high-value products. In addition, we collaborate with top universities to develop innovative materials suitable for future applications. It is worth mentioning that we are also researching materials that can be deposited using other digital printing techniques, such as direct ink writing, extrusion, or FDM.

Conductive/dielectric/pigment/dye/biological fluid/polymer/ceramic/glass/intelligent/soft/rigid

Ink characterization

The first step in digital production based on inkjet printing is material characterization. We have the ability to accurately analyze the physical, chemical, and rheological properties of inks and substrates. Surface and interface tension can be measured to ensure an appropriate balance between the polar and dispersed parts, thereby ensuring the required wetting and adhesion of the ink on the substrate. For example, dynamic surface tension analysis is the key to studying surface tension under short surface aging and thus obtaining the most suitable surfactant. We work closely with multiple external researchers and PhDs on rheological measurement. Enabling us to measure complex viscosity at high frequencies and different temperatures is key to optimizing ink formulations and finding the most suitable spray temperature possible. On the other hand, it enables us to optimize our understanding of the viscoelastic behavior of ink and optimize its formulation to avoid excessive Newtonian behavior, which may lead to many satellites or excessive viscoelastic behavior, thereby preventing ligament rupture. Ink stability and compatibility testing, as well as particle size characterization, have improved our products。

Complex viscosity/tensile viscosity/surface energy/dynamic surface tension/stability/particle size/compatibility

Preprocessing

Based on the physical and chemical properties of the ink and substrate, as well as the required contact angle, pre-treatment steps may be required before printing. In the inkjet field, our platform is equipped with most industry standard technologies, including plasma, corona, or flame treatment. Primer can also be used. We are also committed to new digital preprocessing technologies。

Plasma/Corona/Flame/Primer

printing

The core of this process is material deposition. With ten years of research activities and the hiring of global experts in this field, we have unique expertise in inkjet printing. One of our advantages is the ability to use print heads and electronic devices from most leading manufacturers. Based on customer and process requirements, we will choose the most suitable print head and electronic equipment. Our accumulated experience in different print heads, combined with close cooperation with multiple major print head manufacturers, is one of our biggest assets. We are currently responsible for testing new print heads that have not yet been launched. We are always one step ahead and can provide support for the best choice of print heads and electronic devices. For customers who use adhesive spraying technology, the same applies, as new print heads can unleash the hidden potential of this thriving technology

We are also developing strong capabilities in hybrid advanced manufacturing processes that combine different printing technologies, such as inkjet, direct ink writing, extrusion, or FDM, to overcome the limitations of each technology and allow for digital manufacturing of new products.

Inkjet/mixed additive manufacturing(DIW、MEX)

Post processing

We are equipped with the necessary equipment for post-processing the printing layer and have important professional knowledge in this process step. Depending on the type of ink, UV, NIR, IR, photon, electron beam, or oven only treatments can be used to cure, dry, or sinter each layer. Combining different post-processing steps to process multiple materials is also our ability. There are multiple lights to choose from and can be installed on our multifunctional research printer platform.

UV / NIR / IR /Electron beam/photon/oven

platform

In the past few years, we have established multiple research platforms. This type of platform is very modular and can be modified according to specific requirements of a given process. In addition, a printer can accommodate multiple inkjet print heads and pre/post processing devices. A new hybrid platform combining multiple printing and deposition methods has also been developed. Our facility includes a 6-axis robotic arm for direct molding applications, and we are currently developing technology in this field. It is worth mentioning that we have strong capabilities in ink systems. Finally, all of our platforms are equipped with droplet observation stations, which can directly optimize the waveform on the printer.

It must be emphasized that printing platforms are research platforms and are not suitable for industrial production. Once the process is developed, we can work closely with machine integrators to create industrial machines for our customers using inkjet developed and selected processes and equipment.

Linear axis/robotic arm/ink system/drip observation

product

The digital printing process we have developed can be applied to various application fields. Our strong expertise in the inkjet field enables us to identify and provide innovative solutions for our clients.

Biomedical and Health/Automotive and Transportation/Chemistry and Materials/Earth and Space/Electronics and Automation/Fashion and Design/Manufacturing and Architecture/Energy and Environment