This solution applies microelectronics, microfluidics, and MEMS technologies to various applications in biological systems, including 3D bioprinting, real-time diagnosis, sequencing, drug delivery, and microfluidic biomedical research. Our biosynthetic printing technology has obtained licenses from multiple domestic biological companies and national key experimental units for microfluidic technology, which has a 20-year research and development process。

Process field

- Cell/Gene/Protein Synthesis

- Printing of biological tissues and organs

- Drug delivery

- Disease screening and immediate diagnosis

- Microfluidics and Organ Chips for Biomedical Research and Development

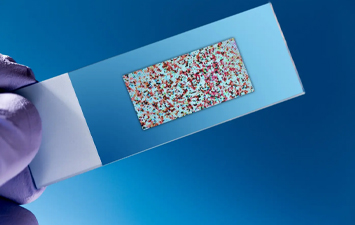

Cells, as the fundamental units of biological structure and function, studying their related biological behaviors, laws, and essence is of great significance for exploring the mechanisms and treatment methods of diseases. The study of cells is a complex engineering task. Cells are located in a complex microenvironment within the human body, with small volumes and diverse types. It is also challenging to perform cell recognition, metabolite detection, internal component analysis, cell structure and function characterization, and analysis of intercellular interactions at the cellular level. Due to the small sample size, low analyte concentration, and complex sample system, cell level analysis poses a huge challenge to traditional research and analysis methods and techniques. The use of dielectric electrophoresis (DEP) in non-uniform electric fields can effectively perform non-contact treatment of single cells. Microwaves are formed by drilling holes on flexible printed circuit boards covered with three layers of metal, thus forming three circular electrodes for each microwave. The implementation device of polystyrene beads and batteries includes a set of microwave tubes and a fluid device for filling physiological saline buffer into the microwave tubes from the bottom and distributing particles into the microwave tubes from the top. Active microwaves are expected to replace single flow cavities or channel chips, with the main advantage of being able to separate cells at different positions, supporting flexible supernatant substitution, simplifying single cell recovery procedures, and ensuring mechanical compatibility with standard high-density microtiter plates. However, there are still high throughput pain points that need to be addressed. In this technology, MicroFab's Jet Drive III and anMJ-A are used to evenly distribute polystyrene beads and cells, resulting in a droplet volume of 0.5 nl. In the experiment, the dilution parameter was 105 cells/ml. By analyzing the statistical distribution of each drop of cells, it was found that when 10 cells were dropped into each well, an average of 0.5 cells were expected, effectively obtaining a single cell。