development tool

From material analysis to system integration, we provide a range of optimization tools and services for ink characterization, print reliability analysis, and print head uation, including DEMO prototypes, print modules, RIP software, cyclic ink supply systems, cyclic cleaning systems, ink droplet observation systems, curing and drying systems, visual inspection systems, Plasma cleaning systems, print quality analysis systems, and other high-performance components and tools that are suitable for your development needs.

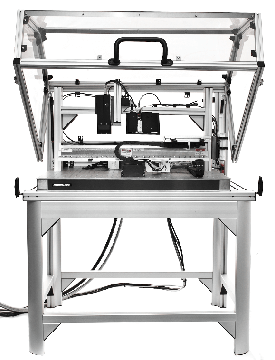

XYPrint Systems

characteristic

The XYPrint system for industrial inkjet is a complete high-precision inkjet system, which is an ideal choice for process development, printing research, direct product decoration, material deposition/additive manufacturing, and small batch production. By using Konica Minolta inkjet print heads, the highest accuracy, repeatability, and reliability can be achieved, aiming to cover the widest possible range of process parameters.

They provide complete flexible control over print head settings, printing parameters, and ink drying/curing, combined with high speed and precision

Sports. As a standard configuration, they come with a simple syringe based ink system that can quickly change ink types and minimize ink waste.

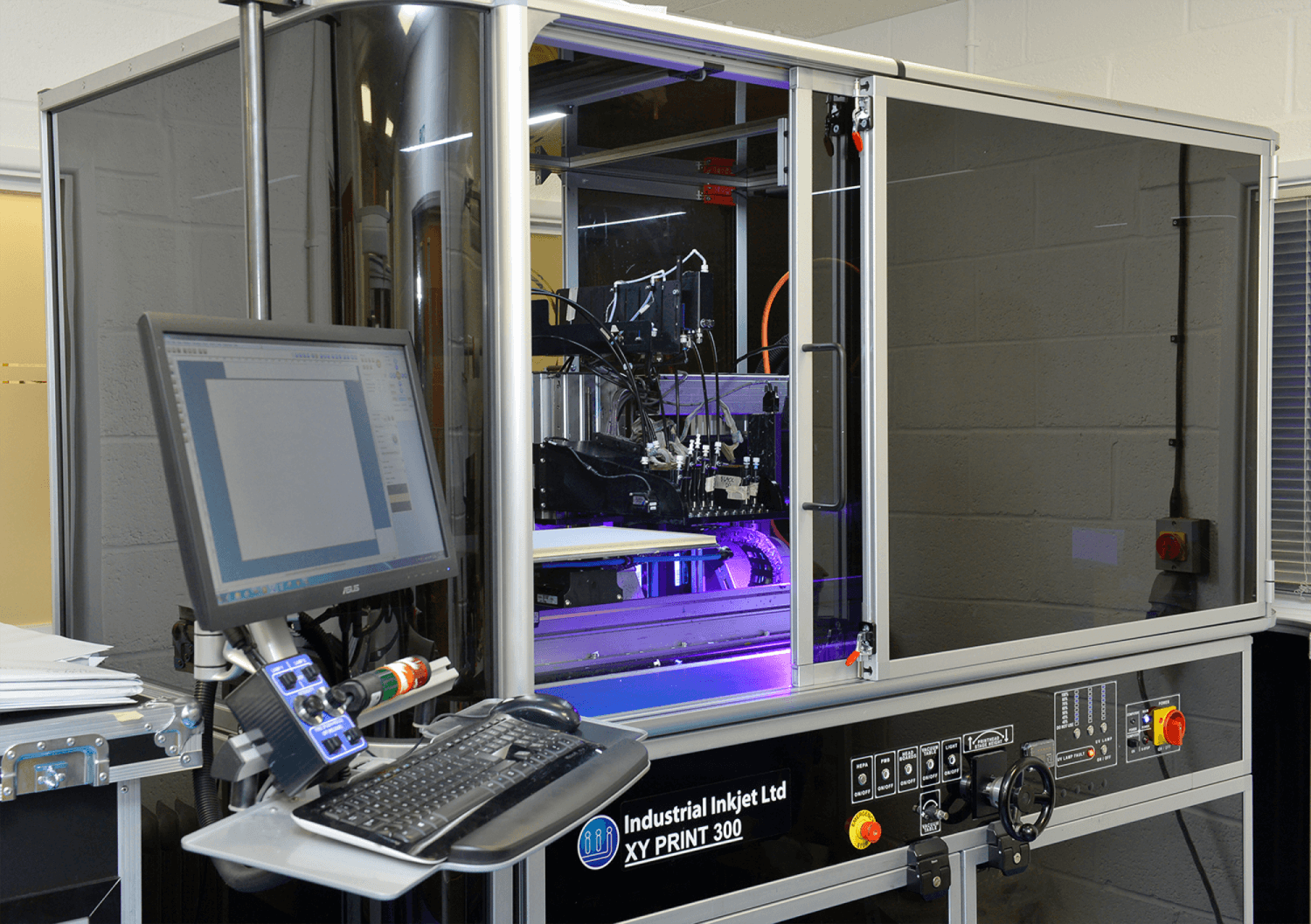

JetXpert

characteristic

Good spraying performance is only half of the development process; You still have to see how all the parts are combined with good vintage printed images. By using the JetXpert printing station to print samples, understand how optimized spraying works on different pre-treatment, substrate, curing methods, and more.

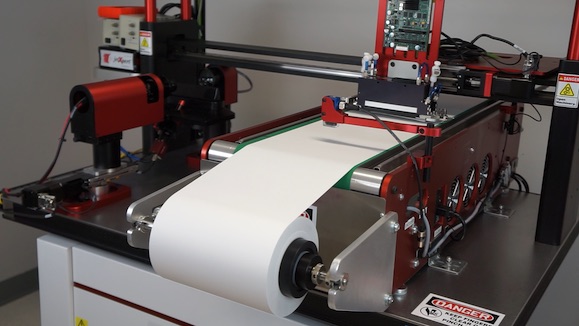

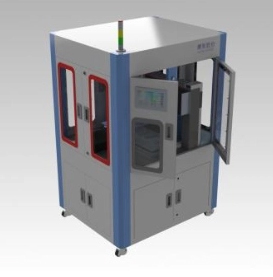

LAB-JET01

A multifunctional laboratory inkjet printing equipment with high flexibility and accuracy, suitable for your various functional material applications, especially for laboratories and development solutions that have not yet been solved. From fast to slow, from small to large, from one to multiple nozzles, optional with UV or infrared curing and drying. We always support you with the highest precision and commitment, introducing new processes and upgrades for you.

characteristic

An open platform that can provide various process parameters

Iteration from R&D development to full day industrial production

Multiple possible applications - compatible with drive devices from all leading manufacturers

Can configure print heads and ink materials from different leading manufacturers

Each configuration can have up to four different print heads

High precision mechanism design and automatic calibration function: including nozzle calibration and nozzle replacement strategy

Clear image user interface

Optional items

Built in UV curing printing

Built in NIR sintering system

Built in Plasma (Plasma Cleaning System)

Adjustable nozzle angle

Six axis and above rotating platform

Spray printing platform temperature control 0-60 ° C

automation

Environmental control: temperature and humidity

Micro Ink Drop Observation System (a very compact and highly integrated measurement system in real production environments, where droplet measurement under different process conditions helps optimize inkjet technology, fluid formulation, and overall system performance)

DMP-2850

Dimatix Materials Printer (DMP) is a desktop (desktop), laboratory material deposition system with an accuracy of up to micrometers. It is designed to micro precisely spray various functional fluids onto almost any surface, including plastic, glass, ceramics and silicon, as well as flexible substrates from films, gel and films.

characteristic

Flat substrate, xyz three-axis platform, inkjet deposition system

Low cost, user refillable piezoelectric inkjet cartridges

Built in droplet spray observation system

Calibration camera for substrate alignment and measurement

PC controlled variable spray resolution and pattern creation, with graphical user interface (GUI) application software

Capable of spraying multiple fluid materials

Heating vacuum platform

Ink cartridge cleaning station

Software included

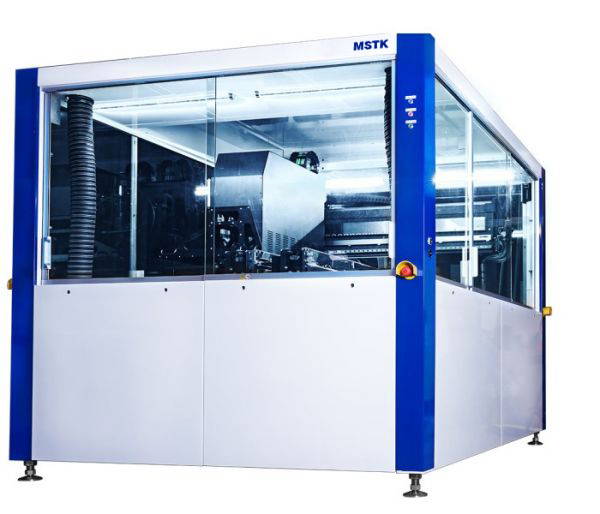

MS LCD-JET X3

DOD on-demand inkjet printing technology is the next generation BM shading layer spraying process for LCD, and manufacturing based on inkjet has significant advantages. Firstly, it avoids the tedious traditional printing production line steps. In addition, inkjet printing greatly reduces capital equipment investment, related labor, land area, chemical usage, and related processing and disposal costs. The use of digital high-precision inkjet technology will greatly increase the production of BM layers.

characteristic

Advanced Bezel border BM shading layer inkjet printing solutionSystem highlights

The substrate size can reach 460x610mm (18x24 ")

With 3 parallel FUJI print head arrays, 2.4-200PL ink droplet size

Integrated Plasma, Thermal/Photocuring, Visual and AOI Process Detection

Equipment cleanliness level<100 Cass

Optional automatic LCD processing module, circular ink supply, and interface with other manufacturing equipment systems