Whether you are looking for a complete(inkjet printing system, driver control engine, ink supply system, or a single print head), you have come to the right place. We provide development services for many different project requirements, and all the information you need to make the best choice is on this page. Alternatively, call us and we will guide you in the right direction。

From software and hardware sales to integrated development of inkjet printing systems, and to complete equipment automation, we can help you achieve a complete solution for industrial printing needs。

R&D strength

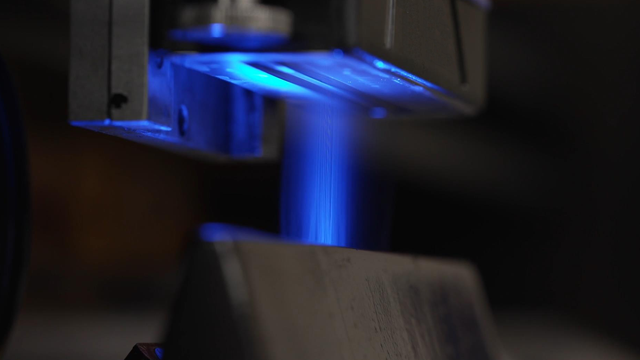

Control algorithm. The so-called mathematical model is the mathematical expression of the dynamic characteristics of a system. It reflects the quantity and logical relationship between system inputs, internal states, and outputs. These relationships provide a basis for computer processing, that is, to derive control algorithms from mathematical models. The so-called computer control is to control according to the prescribed control algorithm. Therefore, the correctness of the control algorithm directly affects the quality of the control system, and even determines the success or failure of the entire system. In the field of digital inkjet printing technology, algorithm logic is often used, including automatic control, optimization design, image processing, etc. In addition, image algorithms refer to the algorithms used to process images. Including image denoising, image transformation, image analysis, image compression, image enhancement, image blur processing, etc.

| landing accuracy | ||

|---|---|---|

|

Spot accuracy is a reflection of the high-precision calibration error of inkjet points and an important parameter for uating the control accuracy of inkjet printing systems。 |

|

| Edge control | ||

|---|---|---|

|

By calculation, optimize and control the peak value and micro droplet accuracy of the edge after inkjet dot forming。 |

|

| Thickness compensation | ||

|---|---|---|

|

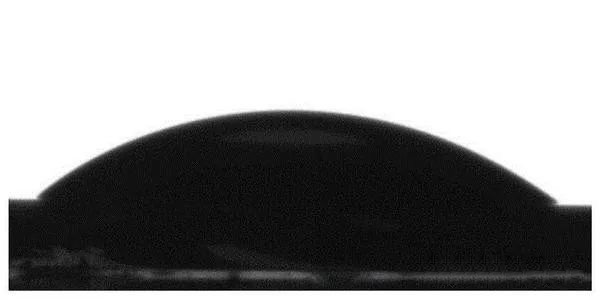

When inkjet droplets spread on the substrate, surface defects and other reasons can cause solutes to "nail" at the contact line, and the droplets will continue to maintain this spreading shape. Due to the fast solvent evaporation rate at the contact line, the solution will transfer and compensate for the evaporated solvent from the middle of the droplet to the edge of the droplet. Finally, solutes deposit on the substrate to form an uneven thin film with thick edges and thin middle layers, known as the "coffee ring" effect. The uniform diffusion accuracy of micro and nano particles is controlled through thickness compensation technology。

|

|

| super inkjet | ||

|---|---|---|

|

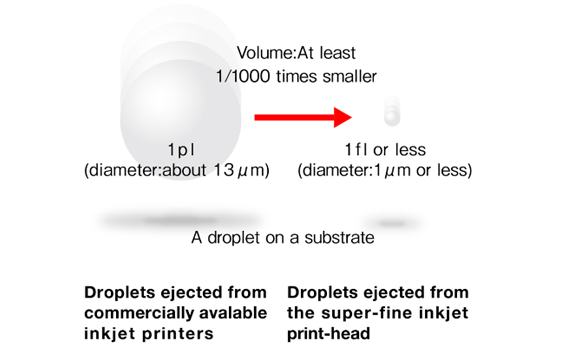

This is a super inkjet technology jointly developed by the Inkjet Research Institute and the Nanometer Research Institute. Compared with the droplet size that inkjet printheads used in inkjet printers on the market can spit out, the size of ultra-fine droplets can reach about 1/10 or less (with a volume of less than 1/1000). In addition, the corresponding viscosity range is 0.5-10000/mPa. s, achieving high-precision non heated discharge that traditional inkjet technology cannot achieve. Therefore, we have achieved remarkable results in the discharge of a wide range of liquid materials, including nanoinks such as Ag and Au, insulating inks, various corrosion inhibitors, adhesives, proteins, etc. |

|

| Corresponding to high viscosity | ||

|---|---|---|

|

Disrupting the existing inkjet concept and achieving high viscosity non heated discharge of 10000/mPa. s。 |

|

| Formation of three-dimensional structure | ||

|---|---|---|

|

Due to the high dryness of ultrafine droplets, the droplets spit out in a liquid state will quickly dry and evaporate. Therefore, by placing them in the same position, a three-dimensional stacking structure can be formed, which is common in the field of biology。 |

|

Cooperation advantages

Application experience. Starting from the sales of printing and driving devices in 2016, we have accumulated application experience in various industry fields. What kind of print heads match what kind of driving electronic devices are applied in what application fields? We have reached the pinnacle of perfection!

| Official partners | ||

|---|---|---|

|

We have third-party strategic cooperation, including technical service support, in areas such as inkjet print heads, driver electronic devices, development/optimization tools, system components, electronic accessories, fluid materials, and various software and hardware products。 |

|

| On demand stocking mechanism | ||

|---|---|---|

|

Starting from establishing strategic cooperation relationships (i.e. signing NDA and other related agreements), we will establish a safety stock stocking mechanism for its quarterly to annual procurement plans, no longer experiencing the business crisis of holding money and queuing up for products to restart, and provide high-quality enterprises with the maximum capacity of stocking support policies。 |

|

| Quality assurance services for core components | ||

|---|---|---|

|

We have "opened up" genuine after-sales quality assurance services in the sales of core components such as printing devices and driving devices, including "refundable" and "repairable" services, which can also help major brands to settle and explore new application areas for technical breakthroughs and cooperation。 |

|

| Financial support policies | ||

|---|---|---|

|

Provide multiple settlement methods for payment transactions, provide maximum financial support to high-quality enterprises, and solve the turnover utilization rate of enterprise cash flow。 |

|

success cases

Core achievements. Our technological achievements will have an impact on science and human health. We hope that through our experienced team, we can completely change the various ways you achieve digital system integration. We believe there are infinite possibilities here. You can find a strategic partner and solution provider here, and confidentiality is also the most important。

| LCD printing solution | ||

|---|---|---|

|

Applying micro droplet jet printing technology to the preparation process of shading layers for various LCD screens such as mobile phones, pads, and televisions, spraying to form thin films with micrometer thickness and good shading characteristics, replacing traditional screen printing processes。 |

|

| Biosynthetic printing solutions | ||

|---|---|---|

|

Using micro droplet spraying technology, develop specialized jet printing equipment, and accurately package 5 or more reagents used for DNA synthesis into column synthesis instruments and chip synthesis instruments with 768-10000 flux reaction chambers。 |

|

| 3D Sand Printing Solution | ||

|---|---|---|

|

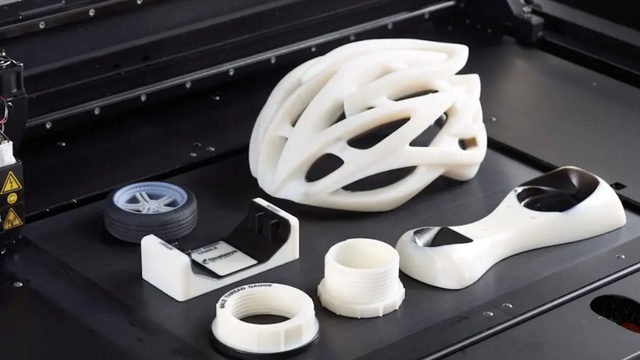

In response to the complex structure and high dimensional accuracy of key components in weapons and equipment, the development of explosive special weapon casting components using sand mold 3DP additive manufacturing technology and special equipment。 |

|