The advantages and disadvantages of circular print heads

Circular print heads have existed for some time and have been widely adopted in the rapidly growing ceramic ink market. But have you ever thought about why it is important for some applications, and should you consider it? After describing the differences in print heads, we looked at some issues in this article and considered the pros and cons from the perspective of complexity and technological advantages.

What is recycling?

The concept of recycled ink is inherent in other types of digital printing systems (such as CIJ), where non print ink droplets are circulated around the ink circuit for reuse. Due to the absence of these unprinted ink droplets in the on-demand inkjet printhead, recycling is carried out inside the printhead. There is continuous ink flow on one side and the other side of the print head。

The advantages of recycling

So why bother with recycling? The two biggest reasons are anti settling (ceramic ink or white ink) and delay (water/solvent ink). In the first case, the continuous movement of the ink avoids the settling and agglomeration of pigments with a higher density than the ink. Secondly, especially for ink that dries quickly, recycling helps prevent the nozzle from drying out due to evaporation losses.

The ink that needs to be heated has another advantage: uniform temperature. If the ink keeps moving, the entire system can maintain more uniform heating instead of temperature fluctuations caused by constantly changing print head duty cycles. This has a positive impact on the uniformity of the print head.

When using an ink system with degassing ability, the ink below the defoamer may degass less when the system is idle. For prolonged periods of non use, this may mean the need to remove new ink. If ink is recycled as part of the printer startup process, the stagnant ink can pass through the degasser again and fill the print head with new ink. The only stagnant ink is the very small volume within the channel itself.

All the above considerations apply to always keeping ink in a sprayable primary state, regardless of chemical composition or printing pause time。

Disadvantages of Recycling

The main challenge in introducing recycling is the complexity of the ink supply system. Compared to gravity ink supply systems, there are more pumps and pressure controls. Simply flushing the nozzle with air pressure can also become quite complex!

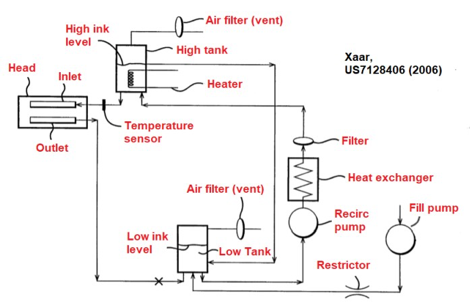

To provide some ideas, we presented an example ink system for recycling, drawing on Xaar's patent. In this scheme, the pressure of the inlet and outlet nozzles is set by the height of the ink storage tank. This is the simplest way to achieve recycling, but it may be inconvenient to place the storage tank on a real printer. In practice, it is more common to use more hardware to create a controlled vacuum on each ink tank。

However, this is not the only problem, because the continuous flow of ink will cause the ink itself to be subjected to additional pressure, especially when the heating system or pumped mechanical agitation will cause foam. Some pumps and ink are not very compatible, and if the materials used by the two are incompatible, repeatedly pumping ink can have negative side effects.

Due to the fact that many one-way inks rely on low surface tension, foaming is also an important consideration. A common failure point of the recycling ink system is when liquid enters the vacuum pipeline, where it can cause serious damage to the solenoid valve or O-ring, which is considered not in the ink channel. A good ink system design assumes that this situation will occur at some point and does something to prevent it. Similarly, the ink itself can be adjusted to low foam, although sometimes there are compromises。

The recycling ink system is bound to be more complex and the biggest obstacle to fully utilizing the latest generation of print heads. In most cases, the benefits outweigh the drawbacks。