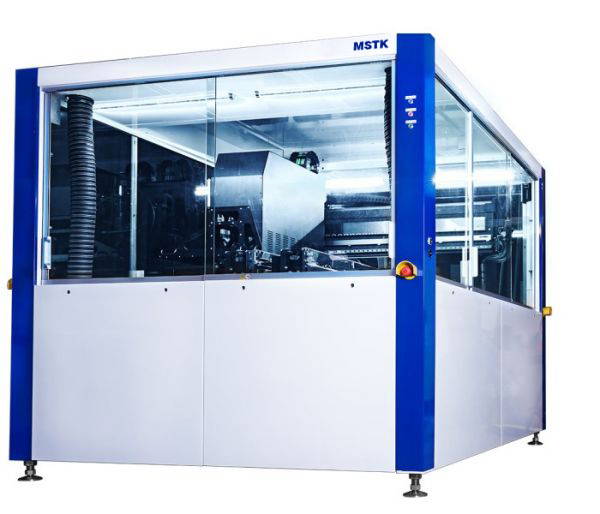

LAB-JET01

A multifunctional laboratory inkjet printing equipment with high flexibility and accuracy, suitable for your various functional material applications, especially for laboratories and development solutions that have not yet been solved. From fast to slow, from small to large, from one to multiple nozzles, optional with UV or infrared curing and drying. We always support you with the highest precision and commitment, introducing new processes and upgrades for you.

LAB-JET01

A multifunctional laboratory inkjet printing equipment with high flexibility and accuracy, suitable for your various functional material applications, especially for laboratories and development solutions that have not yet been solved. From fast to slow, from small to large, from one to multiple nozzles, optional with UV or infrared curing and drying. We always support you with the highest precision and commitment, introducing new processes and upgrades for you.

characteristic

An open platform that can provide various process parameters

Iteration from R&D development to full day industrial production

Multiple possible applications - compatible with drive devices from all leading manufacturers

Can configure print heads and ink materials from different leading manufacturers

Each configuration can have up to four different print heads

High precision mechanism design and automatic calibration function: including nozzle calibration and nozzle replacement strategy

Clear image user interface

Optional items

Built in UV curing printing

Built in NIR sintering system

Built in Plasma (Plasma Cleaning System)

Adjustable nozzle angle

Six axis and above rotating platform

Spray printing platform temperature control 0-60 ° C

automation

Environmental control: temperature and humidity

Micro Ink Drop Observation System (a very compact and highly integrated measurement system in real production environments, where droplet measurement under different process conditions helps optimize inkjet technology, fluid formulation, and overall system performance)