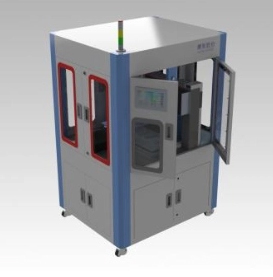

DEMO experimental equipment

The demo system for industrial inkjet is a complete high-precision inkjet system, which is an ideal choice for process development, printing research, direct product decoration, material deposition/additive manufacturing, and small batch production. By using Konica Minolta inkjet print heads, the highest accuracy, repeatability, and reliability can be achieved, aiming to cover the widest possible range of process parameters. They provide fully flexible control over print head settings, printing parameters, and ink drying/curing, combined with high-speed and high-precision movement. As a standard configuration, they come with a simple syringe based ink system that can quickly change ink types and minimize ink waste.

MS LCD-JET X3

DOD on-demand inkjet printing technology is the next generation BM shading layer spraying process for LCD, and manufacturing based on inkjet has significant advantages. Firstly, it avoids the tedious traditional printing production line steps. In addition, inkjet printing greatly reduces capital equipment investment, related labor, land area, chemical usage, and related processing and disposal costs. The use of digital high-precision inkjet technology will greatly increase the production of BM layers.

characteristic

Advanced Bezel border BM shading layer inkjet printing solutionSystem highlights

The substrate size can reach 460x610mm (18x24 ")

With 3 parallel FUJI print head arrays, 2.4-200PL ink droplet size

Integrated Plasma, Thermal/Photocuring, Visual and AOI Process Detection

Equipment cleanliness level<100 Cass

Optional automatic LCD processing module, circular ink supply, and interface with other manufacturing equipment systems